- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

Rugged and weatherproof, this pocket thermal imager quickly scans the temperature of electrical equipment, machinery, and other assets. With an infrared resolution of 120 x 90, this thermal imager features a temperature range of -4 to 752°F (-20 to 400°C). This value-added kit includes the REED R6018 Dual Moisture Meter for FREE.

Rugged and weatherproof, this pocket thermal imager quickly scans the temperature of electrical equipment, machinery, and other assets. With an infrared resolution of 120 x 90, this thermal imager features a temperature range of -4 to 752°F (-20 to 400°C). This value-added kit includes the REED R6018 Dual Moisture Meter for FREE.

Discontinued!

This product has been discontinued and is no longer available.

There is no direct replacement, however we recommend the:

Not what you're looking for? Let’s do a search and help you find what you need.

Features

Rugged, portable camera

Automatically save your images to the right folders with Asset Tagging

Get your preferred amount of infrared everytime

Applications

This dual function moisture meter is capable of detecting moisture in wood and building materials by pin or by running the instrument over the surface area (non-destructive method). The R6018 displays icons to indicate low, medium or high levels of moisture and an audible alert that increases in frequency as detected moisture level rises.

Features

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing. The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

In this article, we cover why use thermal imaging and what to scan, as well as some notes on what to look for, including shaft misalignment.

Read the Article

When conducting infrared inspections, high-quality images that allow for better analysis, presentation, and professionalism are essential.

With a sharply focused image, there is a distinct contrast between areas of varying thermal energy on the surface being inspected. This allows the individual detector elements (also known as pixels) to clearly report the intensity of the energy being focused on them.

When the focus is poor, the incoming energy isn't as concentrated on individual detectors, and their response is skewed. This can lead to temperature measurements that are significantly off, resulting in expensive downtime and possible safety hazards.

Thermal imagers are made with 100% diamond-turned germanium lenses covered with a specialty coating, providing premium quality images.

LaserSharp Auto Focus allows you to select and focus on a specific target

Easily choose and focus on your target

LaserSharp™ Auto Focus uses a built-in laser distance meter that provides both speed and precision. The laser-driven target detection pinpoints the target while the camera focuses to capture a precise, high-quality image. With LaserSharp Auto Focus, you can:

Choose multiple targets at different distances

MultiSharp™ Focus takes multiple images from different focal distances and combines them into one clear image. With a simple point and shoot, you can go from being completely out of focus, to complete focus, throughout the field of view. With MultiSharp:

1.Middleground in focus

2.Foreground in focus

3.Background in focus

Shoot from a distance

Infrared inspections can take you into multiple types of environments with many types of equipment. Interchangeable lenses that require no calibration give you the versatility and the image quality needed to conduct inspections in almost any environment.

High voltage power pole, captured with a TiX560 camera and standard lens

The same power pole captured from the same distance, but with a 2x telephoto lens

The same power pole captured from the same distance, but with a 4x telephoto lens

Whether you are troubleshooting or conducting maintenance inspections, having easy access to more information faster is always a big benefit.

Document information on the equipment you're inspecting

With IR PhotoNotes™, voice or text annotation, you can easily document critical information about each piece of equipment and its location. Each "note" attaches to the image, so you never have to search or match up notes to images.

|

|

Image Info | |

| IR Sensor Size | 320 x 240 |

| Distance to Target | 0.69 m |

Main Image Markers | |

| Name | Temperature |

| Centerpoint | 29.1°C |

Capture digital and infrared images at once

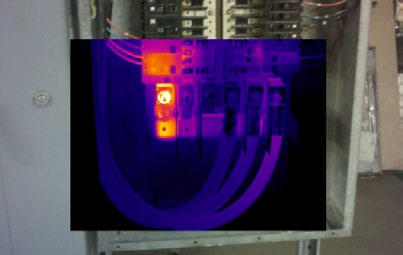

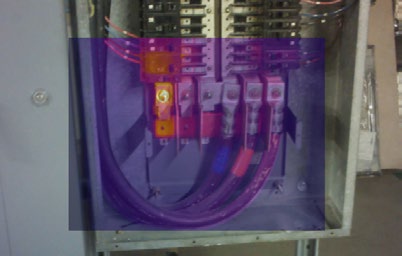

IR Fusion™ technology combines visible light and an infrared image into one, giving you better clarity.

IR Fusion picture-in-picture mode: Ironbow palette

IR Fusion picture-in-picture mode: AutoBlend

IR Fusion color alarm

Seven benefits of on-site infrared inspections

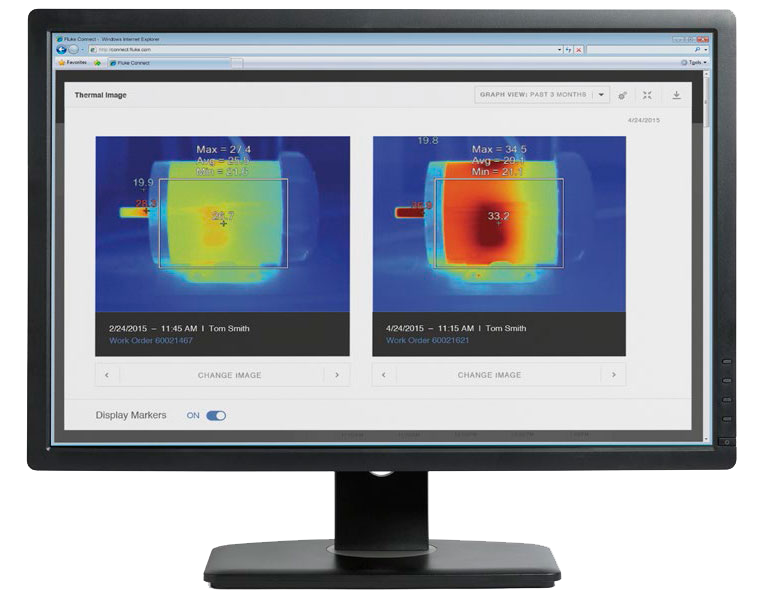

Review thermal images side by side, making it easy to compare today's reading with the baseline or other historical images.

| Infrared Resolution | 120 x 90 (10,800 pixels) |

| Temperature Measurement Range (Not Calibrated Below -10°C) | -4 to 752°F (-20 to 400°C) |

| IFOV (Spatial Resolution) | 7.6 mRad |

| Field of View | 50 x 38° |

| Distance to Spot | 5.417361111111112 |

| Accuracy | ±2°C |

| Focus System | Fixed focus, minimum focus distance 22.8 cm |

| Touchscreen Display | 3.5" (landscape), 320 x 240 LCD |

| Thermal Sensitivity (NETD) | ≤60 mK |

| Frame Rate | 9 Hz |

| Infrared Spectral Band | 8 to 14 μm (long wave) |

| Standard Color Palettes | Ironbow, blue-red, high contrast, amber, hot metal, grayscale |

| Battery | Type: Internal rechargeable lithium ion battery Life: >2 hours continuous (without Wi-Fi) |

| Dimensions | 3.5 x 5 x 1" (8.9 x 12.7 x 2.5 cm) |

| Weight | 0.514 lbs (0.233 kg) |

Featuring a rugged and compact thermal imager with an infrared resolution of 120 x 90, and enhanced infrared inspections right in your pocket for quick temperature scans of electrical equipment, machinery, and other assets. It empowers your team to easily transfer images to your predefined server files with Fluke Connect Desktop.

Pin and Pinless functions detect moisture in wood and building materials (i.e. sheet rock, cardboard, plaster, concrete and mortar).

Fluke engineers have delivered an innovative mobile platform and tool that helps solve everyday problems, allowing you to instantly document measurements, retrieve historical data, and share live measurements with your team. All handled by the Android™ or iOS smart phone you already carry.

Fluke Connect with ShareLive™ video call is the only wireless measurement system that lets you stay in contact with your entire team without leaving the field. The Fluke Connect mobile app is works with over 20 different Fluke products - the largest suite of connected test tools in the world.

Make the best decisions faster than ever before by viewing temperature, mechanical, electrical and vibration measurements for each equipment asset in one place. Get started saving time and increasing your productivity.

By Sat Sandhu, Fluke

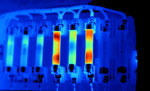

Electronic circuits and components come in a variety of shapes and forms. All electronics operate with current flowing, which in turn leads to power dissipation. This power dissipation manifests itself primarily in the form of heat. Hence a key factor in the design, tests, verification and troubleshooting of all electronics, is heat management. With increasing circuit complexity and or reduction in size, heat management of electronics is taking on a more significant role in the design phase and also in the subsequent phases of test, verification and troubleshooting.

Thermal imaging cameras (TI) are an ideal tool to use in mapping out the heat patterns on electronic circuits and components. Two major advantages of Thermal imaging over contact temperature measurement devices are:

If you would like to learn more about:

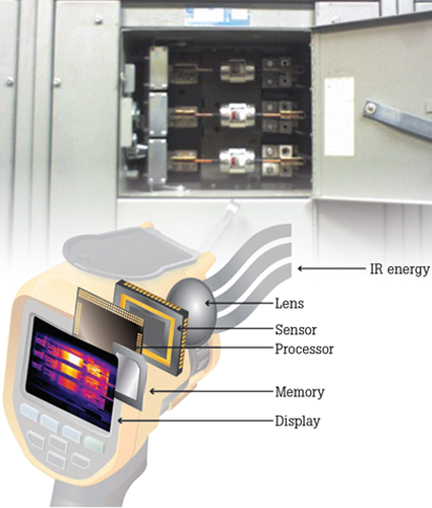

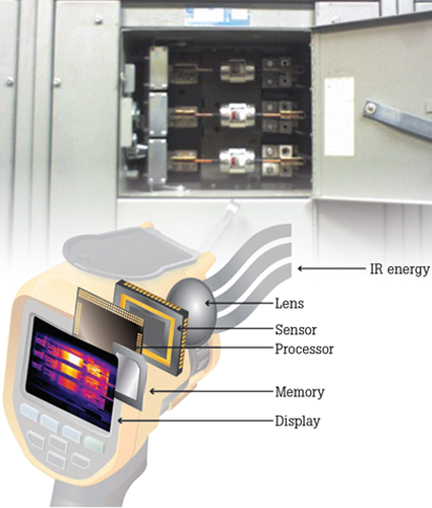

Detailed anatomy of an infrared camera

By Sat Sandhu, Fluke

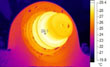

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing.

The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

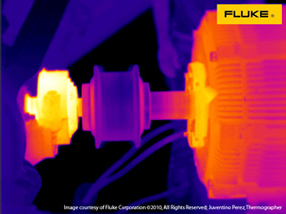

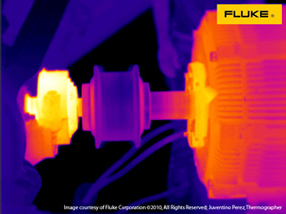

Thermal image of machinery

Why thermal imaging?

Thermal imaging is an effective way to assess equipment condition. Thermal imaging enables you to:

What to scan?

To get started in building heat profiles of your motors, it is a best practice to capture good quality infrared images when the motors are running under normal operating conditions. That gives you baseline measurements of the temperature of components. An infrared camera can capture temperatures of all the critical components: motor, shaft coupling, motor and shaft bearings, and the gearbox.

When you are working with low electrical loads, the indications of a problem may be subtle. Thus a minimum of 40% of design load is recommended (National Fire Protection Association NFPA 70B), and the higher the load, the better. When inspecting in low load situations, be sure to note all possible problems, even if they reflect only a small temperature difference. As a load increases, the temperature will increase too and if a problem exists, expect greater temperature differences at higher loads.

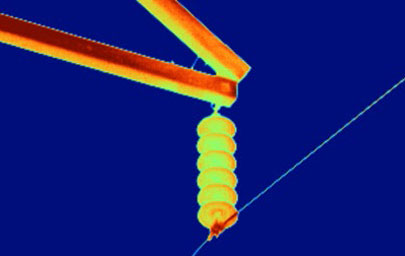

Coupling: This image shows an alignment issue on a motor coupling.

Angular misalignment

The centerline of the two shafts intersect are not parallel.

Combo: This heat pattern indicates an operational motor.

Parallel misalignment

The centerline of the two shafts are parallel but not concentric.

All motors should list the normal operating temperature on the nameplate. Abnormal temperatures, which will show up on a thermal imaging inspection, can be an indication of:

Inadequate cooling because of insufficient air flow. Clearing this issue may only require minor cleaning on the air intake grills.

Power quality issues such as unbalanced voltage or overload or harmonics. All of these will cause excessive heat dissipation.

Impending bearing failure. An overheating bearing is an indication of an impending bearing failure. Bearing condition degrade for a number of reasons:

Insulation failure. With failing insulation of the motor windings the overall motor temperature increases this overheating causes failures and reduces insulation time.

Shaft misalignment. Most misalignment cases are a combination of parallel and angular misalignment (see images above).

Creating regular inspection routes that include thermal images of all critical motor/drive combinations and tracking to those baseline images will help you determine whether a hotspot is unusual or not, and help you verify if the repairs were successful.

Click on a category to view a selection of compatible accessories with the Fluke PTI120-KIT2 Pocket Thermal Imager Kit - Includes the R6018 Dual Moisture Meter for FREE.

| Infrared Resolution | 120 x 90 (10,800 pixels) |

| Temperature Measurement Range (Not Calibrated Below -10°C) | -4 to 752°F (-20 to 400°C) |

| IFOV (Spatial Resolution) | 7.6 mRad |

| Field of View | 50 x 38° |

| Distance to Spot | 5.417361111111112 |

| Accuracy | ±2°C |

| Focus System | Fixed focus, minimum focus distance 22.8 cm |

| Touchscreen Display | 3.5" (landscape), 320 x 240 LCD |

| Thermal Sensitivity (NETD) | ≤60 mK |

| Frame Rate | 9 Hz |

| Infrared Spectral Band | 8 to 14 μm (long wave) |

| Standard Color Palettes | Ironbow, blue-red, high contrast, amber, hot metal, grayscale |

| Battery | Type: Internal rechargeable lithium ion battery Life: >2 hours continuous (without Wi-Fi) |

| Dimensions | 3.5 x 5 x 1" (8.9 x 12.7 x 2.5 cm) |

| Weight | 0.514 lbs (0.233 kg) |

Featuring a rugged and compact thermal imager with an infrared resolution of 120 x 90, and enhanced infrared inspections right in your pocket for quick temperature scans of electrical equipment, machinery, and other assets. It empowers your team to easily transfer images to your predefined server files with Fluke Connect Desktop.

Pin and Pinless functions detect moisture in wood and building materials (i.e. sheet rock, cardboard, plaster, concrete and mortar).

Fluke engineers have delivered an innovative mobile platform and tool that helps solve everyday problems, allowing you to instantly document measurements, retrieve historical data, and share live measurements with your team. All handled by the Android™ or iOS smart phone you already carry.

Fluke Connect with ShareLive™ video call is the only wireless measurement system that lets you stay in contact with your entire team without leaving the field. The Fluke Connect mobile app is works with over 20 different Fluke products - the largest suite of connected test tools in the world.

Make the best decisions faster than ever before by viewing temperature, mechanical, electrical and vibration measurements for each equipment asset in one place. Get started saving time and increasing your productivity.

By Sat Sandhu, Fluke

Electronic circuits and components come in a variety of shapes and forms. All electronics operate with current flowing, which in turn leads to power dissipation. This power dissipation manifests itself primarily in the form of heat. Hence a key factor in the design, tests, verification and troubleshooting of all electronics, is heat management. With increasing circuit complexity and or reduction in size, heat management of electronics is taking on a more significant role in the design phase and also in the subsequent phases of test, verification and troubleshooting.

Thermal imaging cameras (TI) are an ideal tool to use in mapping out the heat patterns on electronic circuits and components. Two major advantages of Thermal imaging over contact temperature measurement devices are:

If you would like to learn more about:

Detailed anatomy of an infrared camera

By Sat Sandhu, Fluke

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing.

The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

Thermal image of machinery

Why thermal imaging?

Thermal imaging is an effective way to assess equipment condition. Thermal imaging enables you to:

What to scan?

To get started in building heat profiles of your motors, it is a best practice to capture good quality infrared images when the motors are running under normal operating conditions. That gives you baseline measurements of the temperature of components. An infrared camera can capture temperatures of all the critical components: motor, shaft coupling, motor and shaft bearings, and the gearbox.

When you are working with low electrical loads, the indications of a problem may be subtle. Thus a minimum of 40% of design load is recommended (National Fire Protection Association NFPA 70B), and the higher the load, the better. When inspecting in low load situations, be sure to note all possible problems, even if they reflect only a small temperature difference. As a load increases, the temperature will increase too and if a problem exists, expect greater temperature differences at higher loads.

Coupling: This image shows an alignment issue on a motor coupling.

Angular misalignment

The centerline of the two shafts intersect are not parallel.

Combo: This heat pattern indicates an operational motor.

Parallel misalignment

The centerline of the two shafts are parallel but not concentric.

All motors should list the normal operating temperature on the nameplate. Abnormal temperatures, which will show up on a thermal imaging inspection, can be an indication of:

Inadequate cooling because of insufficient air flow. Clearing this issue may only require minor cleaning on the air intake grills.

Power quality issues such as unbalanced voltage or overload or harmonics. All of these will cause excessive heat dissipation.

Impending bearing failure. An overheating bearing is an indication of an impending bearing failure. Bearing condition degrade for a number of reasons:

Insulation failure. With failing insulation of the motor windings the overall motor temperature increases this overheating causes failures and reduces insulation time.

Shaft misalignment. Most misalignment cases are a combination of parallel and angular misalignment (see images above).

Creating regular inspection routes that include thermal images of all critical motor/drive combinations and tracking to those baseline images will help you determine whether a hotspot is unusual or not, and help you verify if the repairs were successful.

Click on a category to view a selection of compatible accessories with the Fluke PTI120-KIT2 Pocket Thermal Imager Kit - Includes the R6018 Dual Moisture Meter for FREE.