- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

Wide rangeability of 50:1. Exceptional shut-off and leak rate that meets ANSI/FCI 70-2 Class IV (0.01% of Cv in the closed position).

Wide rangeability of 50:1. Exceptional shut-off and leak rate that meets ANSI/FCI 70-2 Class IV (0.01% of Cv in the closed position).

Discontinued!

This product has been discontinued and is no longer available. There is no direct replacement. Don't worry, we have some options to help you find what you need:

Visit our Check Valves category for similar products.

Or let's do a search and help you find what you need:

Features

Control Valve Trim Styles and Flow Characteristics

Control Valves vary the flow in a system by throttling the valve plug in and out of the valve seat. The corresponding flow rate through the valve is based on the valve plug and seat type, which is part of the valve trim. Dwyer Instruments, Inc. offers several flow characteristics, needle plugs, and restricted trim options for the Hi-Flow™ Control Valve series.

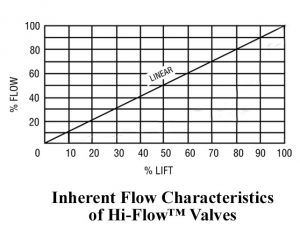

There are two types of inherent flow characteristic trim styles available in the Hi-Flow™ product line: Linear and Equal percentage.

With linear trim, equal increments in plug travel provide equal increments of flow change (as in a linear function).

A linear valve characteristic is nearly always desirable when the major load change in the process requires merely a change in flow through the valve. Such a load change could be a controller set point adjustment, or some other load in the process itself, calling for a new valve position.

With equal percentage trim, equal increments of plug travel provides uniform percentage increases in flow (as in an exponential function).

An equal percentage valve characteristic is desirable when the time constants are large and the characteristic frequency of the system changes as the load varies.

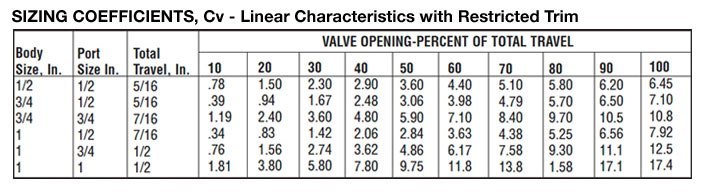

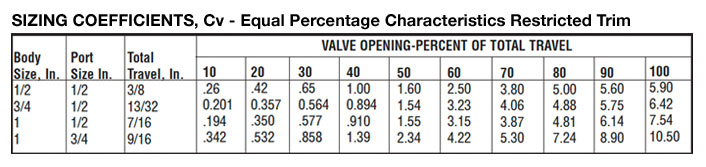

The Hi-Flow™ Series offers restricted trim (which has a smaller port size) in the 3/4″ and 1″ size valve body. This allows a reduction in flow rate through the valve without a reduction in pipe size. The 1″ valve body is available with 3/4″ and 1/2″ port sizes, and the 3/4″ valve body is available in a 1/2″ port size. The restricted trim is available in either linear or equal percentage flow characteristics. Shown below are flow rate charts with the drop in flow coefficient values for these restricted trim options

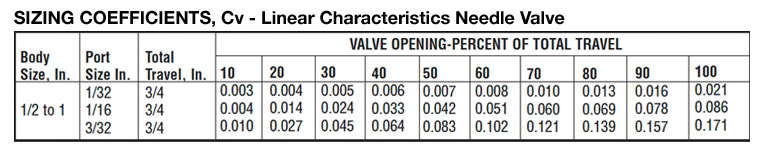

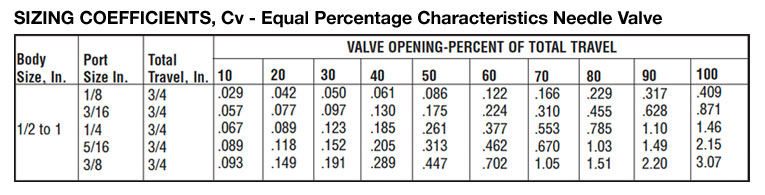

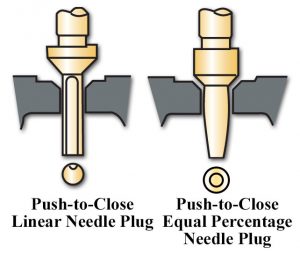

The Hi-Flow™ Series also offers needle plugs that reduce the orifice size considerably for controlling very low flows. The needle plugs are available in linear or equal percentage flow characteristics.

Needle plugs are available in the 1/2″, 3/4″, and 1″ valve body sizes. The linear needle plug sizes are 3/32″, 1/16″, and 1/32″, and the equal percentage plug sizes are 3/8", 5/16", 1/4", 3/16", and 1/8". Shown below are flow rate charts with the drop in flow coefficient values for these needle plug options.